I’m a big fan of electric skateboarding, daily driving my Wowgo 3X pretty much anywhere around town. The 3X is a longboard style board, quite comfortable and extremely fun carving. That said however, for a while now I’ve been looking for something smaller and easier to carry to complement it.

I managed to find a deal for a broken Ownboard W2. It had a good drive, ESC and remote, but a dead battery, broken housing and wheels. I decided to fix it while also swapping the deck for something smaller from a used cruiser board. This is how this build was born.

I described the battery rebuild in a separate post right here. With the battery done the next thing on the list was the battery housing as the original one was damaged. In commercially available electric skateboards the battery housings are usually injection molded. In my case with an order quantity of 1 – FDM 3D printing makes a whole lot more sense.

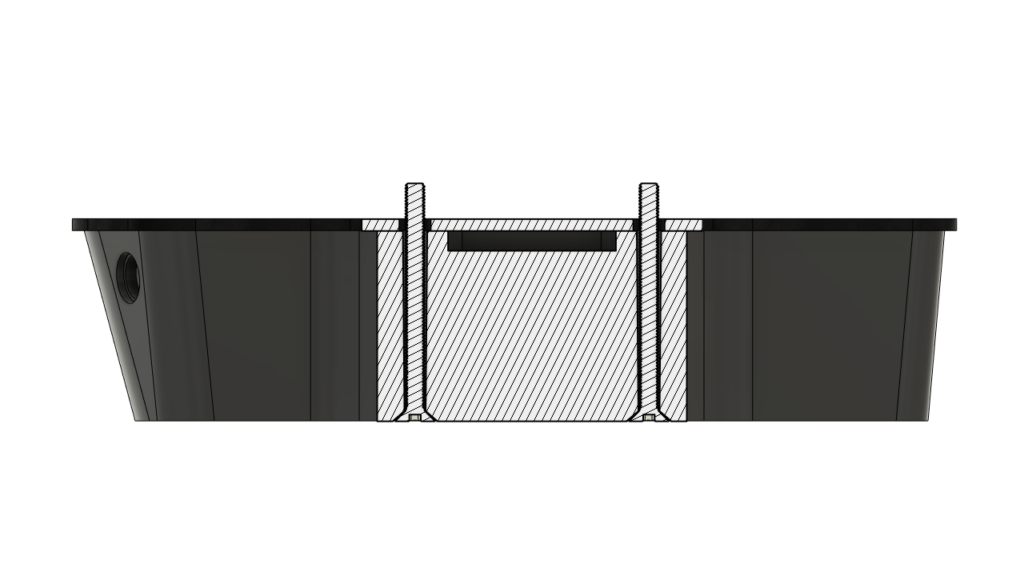

The FDM process does put some limitations on the design of battery housing, mainly because of the limited inter-layer adhesion. I decided to reinforce the Z axis with a use of screws going through the entire depth of the housing. I used 4 Flat Countersunk M5x60 screws to keep everything flush.

The housing is slightly bigger than the battery pack in order to fit some foam damping as well as leave room for cables and connectors. I also added a small hole on the front to fit a 5.5×2.5 charging port.

The housing was 3D printed in ABS material on my enclosed Voron 2 machine. The battery pack does produce some heat during use and charging therefore I wanted to stay away from PLA material because I feared the low heat deflection temperature of around 55°C might not be sufficient. ABS being closer to 97°C is a safer choice.

Going forward I removed the stock griptape from the board and sanded the deck. I milled a small channel on the top side with through holes on each end to route two AWG 10 battery cables, this way the cable is invisible after a new griptape is applied. I painted the wood dark brown. With the new housings positioned I drilled new mounting holes and used wood threaded inserts to add threads for the screws.

I also decided to design and add a skid plate to the kicktail of the board to prevent quick wear of the deck. The design has small curve in order to perfectly fit the board. I printed the skid plate with 100% infill. The model is small, quick to print and very easy to replace with just two screws holding it in place.

Finally I applied and trimmed the new grip tape and the build was done. With the rebuilt battery the board has a range of around 30 km. Compared to the longboard it has a much tighter turning radius making it easier to turn (thanks to the shorter wheelbase). It’s easier to pick up thanks to the kicktail and takes less space in the boot of a car. That said, with a top speed roughly the same as the bigger board at around 40 kph, it is much scarier because of the much narrower stance 🙂