My fascination with the Voron project began back in 2018 when the Voron 2.0 3D printer was still in development. Many of the 3D model files were already available, but the instructions and most importantly the BOM was missing at that time. Together with the community I helped create what was called a “Guerrilla BOM” for the v2.0 and I started purchasing parts. Before all of them even arrived the release of v2.0 was scrapped and the v2.1 was officially released. Fortunately for me, most of the parts were compatible.

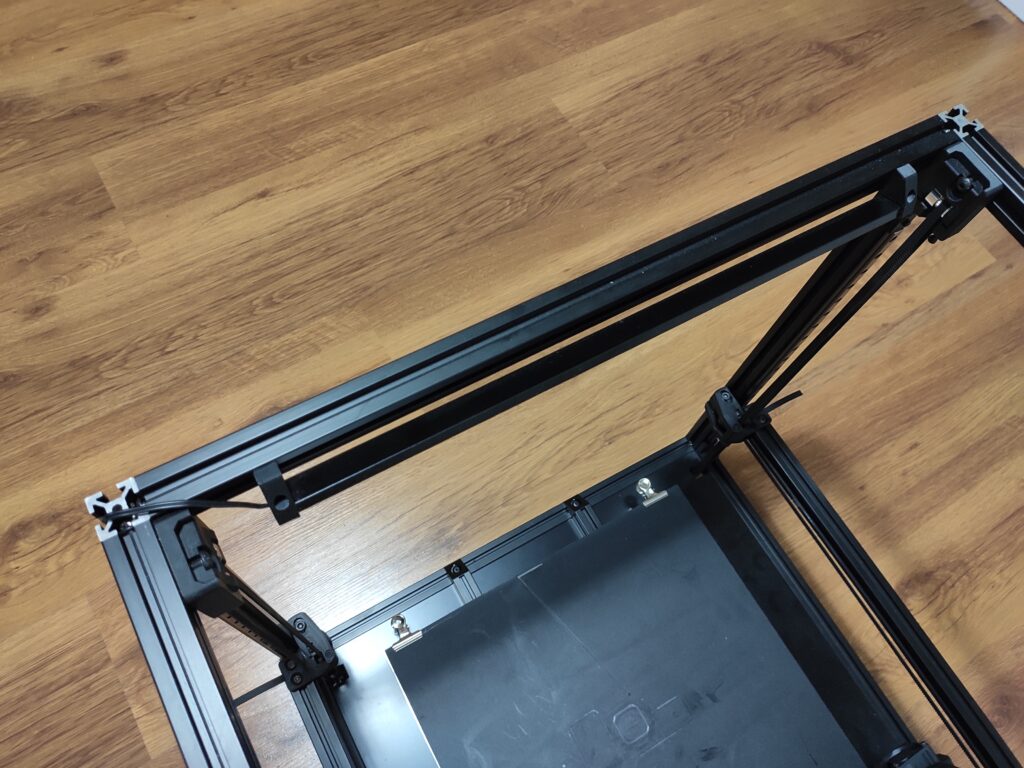

I started the build with the frame made out of 2020 Misumi profiles. I opted for the 350×350 mm build area size. the biggest one officially supported. I used my existing 3D printer to manufacture the plastic parts. I did have to create a makeshift, temporary enclosure for that task as Voron requires all the crucial printed parts to be ABS. After the prints were done I basically cannibalized that machine and reused some of the parts such as motors and electronics in the Voron build.

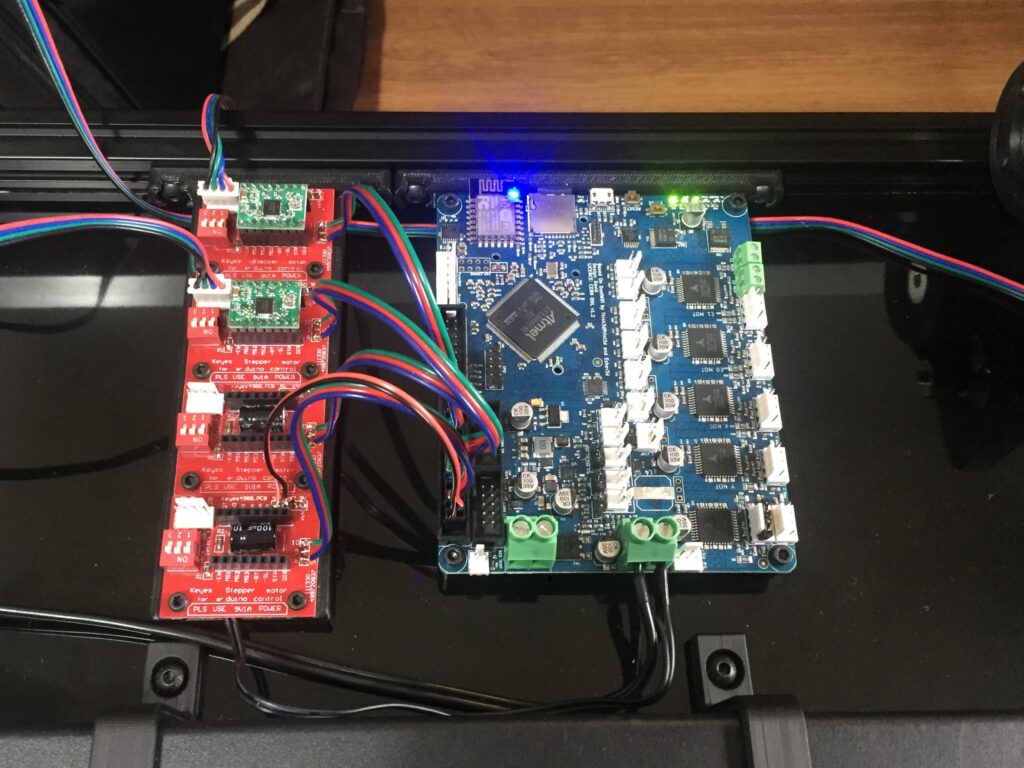

For the brain of my Voron, I opted for a DUET 2 WiFi control board. I already had experience with and I was a big fan of it’s performance, capability, ease of configuration and use. DUET 2 on it’s own can support up to 5 independent stepper drivers. Voron 2 however has 7 of them. Additional stepper drivers can be easily added with the use of a DUEX board, but as it was quite expensive I decided implement a DIY stepper expansion solution using 4 external stepstick (driver) PCBs. The cost for this necessary capability dropped from around 150$ down to 10$.

The machine is using an AC powered platform heater and a fanless 24V 200W power supply. The power draw from all 7 stepper motors, electronics, fans, LEDs and the hotend heater never really exceeds 120 W. Notably I wanted the machine to be completely silent when not in use. In 3D printers idle noise is usually generated by hotend or PSU cooling fans. In my case because the PSU is fanless the only problem was the hotend cooling fan. Fortunately the DUET electronics allowed me to connect and configure the fan to only be active when hotend temperature exceeded 50°C. This way it automatically turned on and off when needed.

With the electronics installed it wasn’t long before the machine started melting plastic. On April 5th, 2019 my Voron received it’s serial number from the community – number 137. The machine was 80 % done by this point, it was a significant milestone. Not long after I also added polycarbonate transparent panels fully enclosing the printing chamber. I opted for polycarbonate instead of acrylic because of it’s self extinguishing properties in case of a fire.

You could say a 3D printer is never truly complete unless You modify it, thus making it truly yours :). Once the initial build was done I got into creating mods for the machine. Some examples:

- Internal LED lighting

- Internal Spool Holders

- Beltchains inspired by Voron 2.0 (never officially adopted)

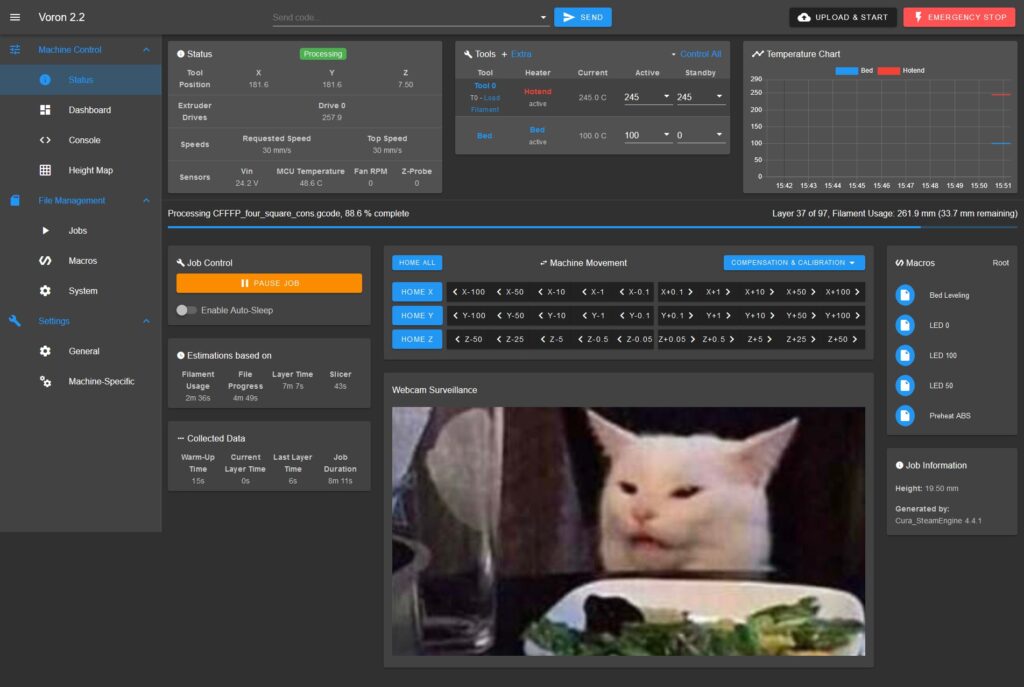

- Redesigned Duet Web Control webpage

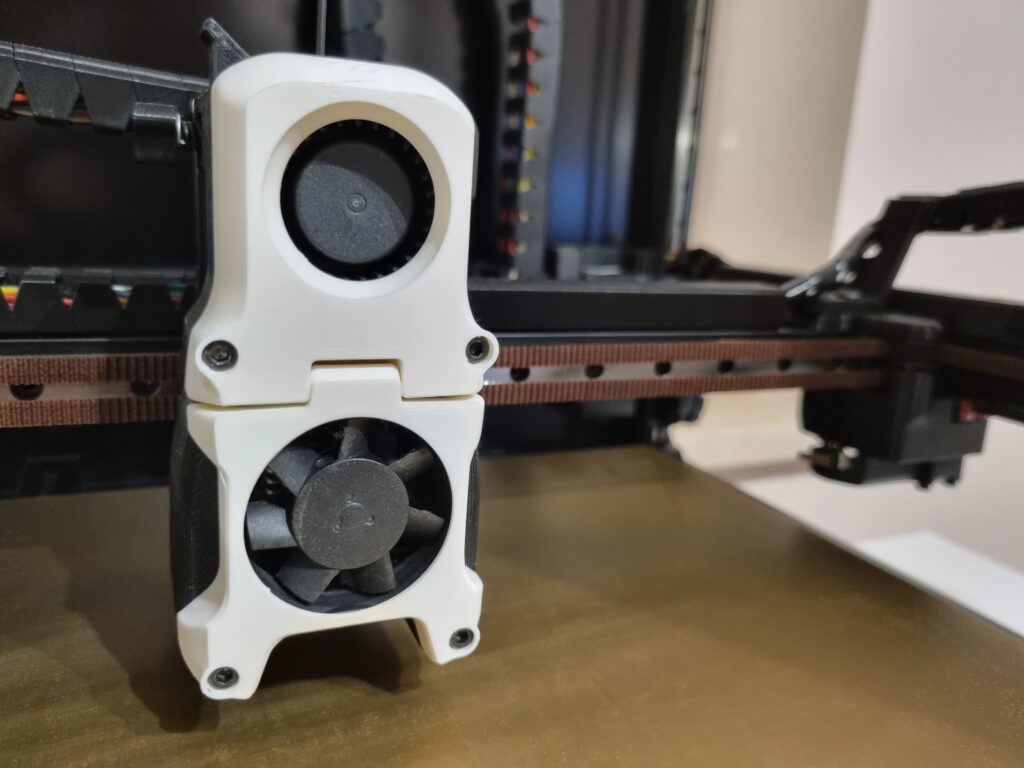

Some time later my Voron 2.1 got updated up to a Voron 2.4 specification with a new direct drive extruder, PEI plate, MGN12 X axis rail and some visual stuff like bottom side skirts (finally).

Building this machine was as much fun as it was a learning experience. I had a chance to learn a lot about design, electronics and configuration of 3D printers which later proved very useful in my professional career. The amazing community around the Voron project made solving any problem a real breeze.